Your applications

Thermal insulation

Insulation is used wherever the manufacturing process requires or generates process heat.

It protects people and system components from excessive heat, reduces cycle and warm-up times and ensures efficient use of energy.

In many cases, the process imposes additional conditions on the insulation, which must be taken into account in the choice of material. For instance, mechanical strength, chemical resistance or electrical insulation capacity can also play a key role.

Overview of all applications

Sample Solutions

Threaded bars made of GFRP material

Threaded bars made from glass-fibre reinforced plastics are suitable for a wide range of applications. The threaded bars are used to insulate threaded connections.

Insulating components for plastic welding technology

A plastic welding process generates heat that must be insulated. The following applies: The shorter the cycle times, the greater the amount of energy that needs to be introduced into the joining zone.

Complex 3D components for thermal insulation

The manner in which these insulation materials are implemented can be as varied as the requirements placed on them: from a simple intermediate layer all the way to complex 3D components with various material combinations that are produced on a 5-axis…

Nuts made of GFRP material

Our nuts made from glass-fibre-strengthened plastics are available as square or hexagonal nuts.

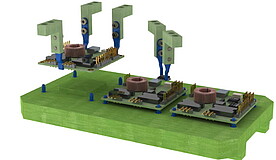

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Heat insulation board

DOTHERM and ISOCOS offer heat protection plates that are precisely adapted to the respective process requirements in terms of material, compression strength, temperature resistance and dimensional stability.

Non-material-specific insulation solutions

In many industrial applications, it makes sense to use multi-layered materials or material combinations.

Workpiece holder/carrier

The exact positioning of components is particularly important for series production. Here, multiple components are frequently welded, bonded, riveted, soldered, etc. at high cycle rates to form assemblies.

Show more Show less