Your applications

Positioning

If pieces of sheet metal are welded to one another, they must be positioned exactly relative to each other, as even slight inaccuracies will impair the quality of a processed component. Ceramic positioning and fixing pins can withstand weld spatter, extremely high temperatures and high mechanical loads much better than conventional pins made from hardened steel – proven by the fact that the service life of ceramic positioning elements is 40 times longer.

As a result, positioning and fixing pins made from high-performance ceramics do not need to be replaced as frequently, plants can be operated with fewer interruptions while process and servicing costs are significantly lower.

Positioning elements made from high-performance ceramics are used at various points in car manufacturing, including in car body construction.

Sample Solutions

Locating pin

During the manufacturing process for all types of products, there is a need to pick up and align parts or components. Since DOCERAM locating pins are ceramic parts made from Cerazur, they are wear-resistant, electrically insulating and do not suffer…

Positioning pin

Positioning pins are used for the controlled positioning to extremely fine tolerances of components and moulded sheet metal parts.

Spacer sleeves

Spacer sleeves made from high-performance ceramics are used whenever a defined clearance must be created between two components or in situations where a distance must be bridged.

Blank holders

Blank holders serve to hold components securely in position in the application. They are typically held against a surface/contour.

Vacuum-tight components

Many technical processes such as semiconductor fabrication, medical technology or material testing are conducted in a vacuum.

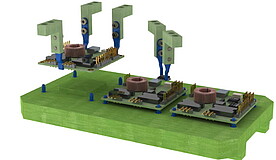

Workpiece holder/carrier

The exact positioning of components is particularly important for series production. Here, multiple components are frequently welded, bonded, riveted, soldered, etc. at high cycle rates to form assemblies.

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.