Your challenges

Wear in the process

Wear (material removal) on components is an important risk factor during the production process. Due to the external application of loads, standard materials frequently show signs of heavy wear. These load applications can include grinding, rolling, percussive, scratching, chemical and thermal stresses.

All signs of wear in the process represent a high risk to the security of current production. It is essential to prevent or even predict the occurrence of wear.

Sample Solutions

Headed dowels

Headed dowels are used to hold and determine the position of tools and fixtures. The advantage is that it enables punctiform placement of a workpiece. The punctiform support is easy to clean and excludes the possibility of contamination caused by…

Locating pin

During the manufacturing process for all types of products, there is a need to pick up and align parts or components. Since DOCERAM locating pins are ceramic parts made from Cerazur, they are wear-resistant, electrically insulating and do not suffer…

Spacer sleeves

Spacer sleeves made from high-performance ceramics are used whenever a defined clearance must be created between two components or in situations where a distance must be bridged.

Dosing components

The dosing systems used in the field of dosing technology are being continuously optimized and advanced.

Bobbin cores

Bobbin cores are usually round parts with a large groove into which a copper coil is wound. This coil induces a magnetic field in the centre of the coil.

Forming rollers

Forming processes place very high demands on the wear resistance and stability of the tools and mountings used. High surface qualities are required.

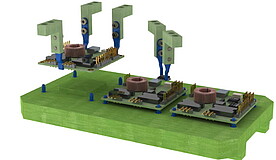

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Show more Show less