Volcera is a silicon nitride and is characterised by a range of properties that make it a very interesting choice for industrial applications. Thanks to its high strength and low thermal expansion coefficient, the Volcera material is ideally suited to alternating thermal stresses.

Even at temperatures of around 1,000 °C, components made from Volcera can still transmit very high forces and is therefore extremely well suited to soldering and welding applications.

| DOCERAM Bezeichnung DOCERAM Type |

Unit | A-132 | A-141 | Z-141 | Cerazur | Volcera 141 | EvoCera |

| Material Material |

- | AI2O3 >99,7% |

AI2O3 >99,99% |

ZrO2 Y-PSZ | ZrO2 Y-PSZ | Si3N4 | - |

| Farbe Colour |

- | elfenbein ivory |

hellrosa pink |

weiß white |

blau blue |

grau, schwarz grey, black |

- |

| Dichte Density |

(g/cm3) | 3.9 | 3.9 | >6.04 | 6 | 3.2 | 5.9 |

| Biegefestigkeit Flexural Strength |

(MPa) | 390 | 390 | 1200 | 1300 | 1000 | 400 |

| Druckfestigkeit Compressive Strength |

(MPa) | 3900 | 3900 | 3000 | 3000 | 2500 | 3000 |

| E-Modul Modulus of Elasticity |

(GPa) | 390 | 390 | 205 | 205 | 320 | 218 |

| Bruchzähigkeit Fracture Toughness |

(MPa√m) | 5.2 | 5.2 | 8 | 12 | 6.4 | - |

| Weibull Modul Weibull Modulus |

- | 12 | 12 | 12 | 25 | 14 | 50 |

| Vickers Härte Vickers Hardness |

(HV 0.5) | 2000 | 2000 | 1300 | 1150 | 1650 | 1047 |

| Wärmeausdehnung Thermal Expansion Coefficient |

(10 -6K-1) | 5.5-8.4 | 5.5-8.4 | 10 | 10 | 3.4 | 11.1 |

| Wärmeleitfähigkeit Thermal Conductivity |

(W/mK) | 28 | 28 | <2 | <2 | 22 | 3.55 |

| Temp. Wechselbeständigkeit Thermal-Shock Resistance |

(ΔT°C) | 120 | 180 | 290 | 280 | 830 | - |

| Maximale Einsatztemperatur Maximum Operating Temperature |

(°C) | 1700 | 1700 | 1000 | 1000 | 1200 | - |

| Spez. Widerstand bei 20°C Volume Resistivity at 20°C |

(Ω cm) | > 1017 | > 1015 | > 1010 | > 1010 | > 1011 | - |

| Durchschlagsfestigkeit Dielectric Strength |

(kV/mm) | 22 | 30 | - | - | 20 | - |

The values listed were determined on standard test specimens. The material properties may deviate from these values depending on the applications and component geometry. Please contact us for precise clarification of the material suitability. Other technical data on request. Subject to technical modifications and errors. 2014 edition.

Sample Solutions

CAD portal

Our components from high-performance ceramics can also be configured on-line. All product variants are stored in our CAD portal - you can make adjustments quickly and easily by entering the parameters for your welding process.

Dosing components

The dosing systems used in the field of dosing technology are being continuously optimized and advanced.

Flow measurement

One of the most important variables in industrial measurement technology alongside temperature, pressure and force is flow measurement, which is one of the fundamentals of process automation.

Blank holders

Blank holders serve to hold components securely in position in the application. They are typically held against a surface/contour.

Sensor protection

Examples of sensor protection include wear caps, wear disks or wear plates, which are used to protect the sensor behind.

Punching stamps

Punching stamps must repeatedly punch a contour in a predetermined geometry into a sheet.

Forming rollers

Forming processes place very high demands on the wear resistance and stability of the tools and mountings used. High surface qualities are required.

Vacuum-tight components

Many technical processes such as semiconductor fabrication, medical technology or material testing are conducted in a vacuum.

Non-material-specific insulation solutions

In many industrial applications, it makes sense to use multi-layered materials or material combinations.

Workpiece holder/carrier

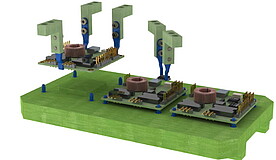

The exact positioning of components is particularly important for series production. Here, multiple components are frequently welded, bonded, riveted, soldered, etc. at high cycle rates to form assemblies.

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Show more Show less