Centring pins are manufactured entirely from ceramic and are used for centring nuts on metal sheets. New materials such as Usibor, in particular, justify the use of ceramic – ceramic components eliminate the growing occurrence of wear problems and maintain process reliability.

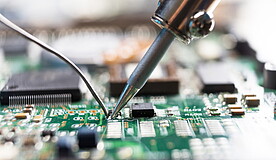

The ceramic pins are used during projection welding. Their purpose is to catch the metal sheet and centre the nut at the relevant point. Our centring pins perform to their full potential when used in conjunction with our “ModulMaster” welding device. Thanks to the modular structure, the components can be precisely adapted to the respective performance requirements.

Ceramic welding centring pins boast a service life up to 40 times longer than that of steel pins. High-performance ceramic also impresses here thanks to its high temperature resistance and consistent hardness as well as flexural strength and impact resistance. In addition, it prevents the adhesion of weld spatter. Its electrical insulating property offers a further advantage.

The extended service life compared with conventional pins shows the possible cost savings. Fewer downtimes due to pin changes and longer maintenance intervals also have a noticeable impact on costs - to say nothing of the unforeseeable costs of complaints due to defective welding.

Centring pins are manufactured from Cerazur and Volcera (to cope with temperature problems caused by excessively high cycle times).

Compatible Materials

Zirconium oxide

Zirconium oxide is an inorganic non-metal material that belongs to the group of oxide ceramics.

Latest applications

Positioning

Positioning elements made from high-performance ceramics are used at various points in car manufacturing, including in car body construction.