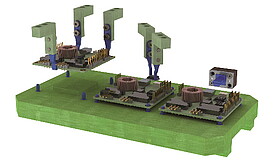

Our ceramic test plugs perform multiple tasks simultaneously. First of all, of course, they perform functional tests and the programming if necessary. The swash circumference test then checks the pluggability of the assembly. The swash circumference describes how far the contact pins are permitted to deviate from the target position in the X and Y direction. Its size is specified as a diameter. If the pins deviate from it, they are pressed against the very hard but fracture-resistant ceramic test plug during the test process and the drive system stops. This approach ensures that rejects are easily detected.

Beneficial characteristics of the ceramic test plugs:

- Extremely wear-resistant ceramic for substantially longer service lives

- Non-magnetic

- Can also be used to realise the smallest geometries: 0.3 mm wall thickness

- High technical purity: no abrasion in the component, no incorrect measurements, no premature failure of the pogo pins

Ceramic

Swash circumference plug-in test

DOCERAM test adapters made from high-performance ceramics for reliable 100% testing of vehicle electronics are already in successful use as standard by leading automotive suppliers.

| Properties | Unit | Cerazur | Aluminium oxide |

| Composition | - | ZrO2 Y-PSZ | AI2O3 >99.7% |

| Colour | - | blue | ivory |

| Density | (g/cm3) | 6 | 3.9 |

| Flexural strength | (MPa) | 1300 | 390 |

| Compressive strength | (MPa) | 3000 | 3900 |

| E-modulus | (GPa) | 205 | 390 |

| Impact resistance | (MPa m1/2) | 12 | 5.2 |

| Weibull modulus | - | 25 | 12 |

| Vickers hardness | (HV 0.5) | 1150 | 2000 |

| Thermal expansion | (10-6K-1) | 10 | 5.5-8.4 |

| Thermal conductivity | (W/mK) | <2d> | 28 |

| Thermal-shock resistance | (ΔT°C) | 280 | 120 |

| Maximum operating temperature | (°C) | 1000 | 1700 |

| Specific resistance at 20°C | (Ω cm) | > 1010 | > 1017 |

| Dielectric strength | (kV/mm) | - | 22 |