Your applications

Handling

Handling refers to the general management or transportation of parts and components in production processes – between the respective production steps. This includes, for example, positioning, aligning, gripping and holding components.

Components with sensitive surfaces must not be damaged or soiled. The handling of highly abrasive components or media will very quickly cause wear on handling elements in general, which can result in a situation where components can no longer be reliably positioned for the process.

Thanks to the extreme wear resistance, exact positioning of electronic components is permanently guaranteed.

Overview of all applications

Sample Solutions

Coated components

Components with a wide variety of coatings are characterised by different properties depending on the type and material of the coating. Many coatings are used to achieve an extended service life as well as improved chemical resistance of the…

Slide rails

If metallic materials are used for guides or rails, wear due to friction is unavoidable. Slide rails made of DOTHERM materials offer the benefits of excellent friction and sliding properties, high wear resistance and thermal stability.

Gripper fingers

Gripper fingers have component-specific contours at their ends that enable them to pick up, grip, transport or guide components. They are used primarily in electronics manufacturing.

Blank holders

Blank holders serve to hold components securely in position in the application. They are typically held against a surface/contour.

Positioning pin

Positioning pins are used for the controlled positioning to extremely fine tolerances of components and moulded sheet metal parts.

Test plugs

Test plugs are assemblies made from different high-performance materials. They are used as standard for reliable 100% testing of vehicle electronics by leading manufacturers in the automotive industry.

Goods carriers

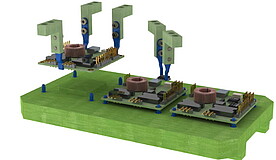

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Workpiece holder/carrier

The exact positioning of components is particularly important for series production. Here, multiple components are frequently welded, bonded, riveted, soldered, etc. at high cycle rates to form assemblies.

Insulating components for plastic welding technology

A plastic welding process generates heat that must be insulated. The following applies: The shorter the cycle times, the greater the amount of energy that needs to be introduced into the joining zone.

Show more Show less