Your challenges

Process reliability

Wear, deformations and breakages are critical phenomena in the production process. The function of quality-relevant components made from conventional materials can quickly deteriorate in very challenging application areas.

Keeping processes running is the fundamental challenge in the manufacturing industry. The ability to make wear or impending defects visible is a desirable function. To achieve this, materials must be resistant in combination with products or even intelligent.

Sample Solutions

Insulating components for plastic welding technology

A plastic welding process generates heat that must be insulated. The following applies: The shorter the cycle times, the greater the amount of energy that needs to be introduced into the joining zone.

Complex 3D components for thermal insulation

The manner in which these insulation materials are implemented can be as varied as the requirements placed on them: from a simple intermediate layer all the way to complex 3D components with various material combinations that are produced on a 5-axis…

Positioning pin

Positioning pins are used for the controlled positioning to extremely fine tolerances of components and moulded sheet metal parts.

Sensor protection

Examples of sensor protection include wear caps, wear disks or wear plates, which are used to protect the sensor behind.

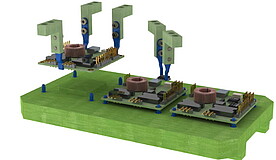

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Show more Show less