Insulating materials for heated presses must keep pace with ever-increasing requirements. In general, the following properties are of decisive importance for insulating materials in heated presses:

- Long-term thermal stability

- Low setting behaviour (compressive strain) under operating conditions

- Resistance to static and dynamic compressive load (load change) – resistance to chemicals and oil

As a particular consequence of the very high specific compressive loads sometimes applied (up to approx. 90N/mm²), glass-fabric or glass-fibre reinforcements in combination with fillers and resins are generally used. However, inorganic composite materials are also used in the case of low specific pressures.

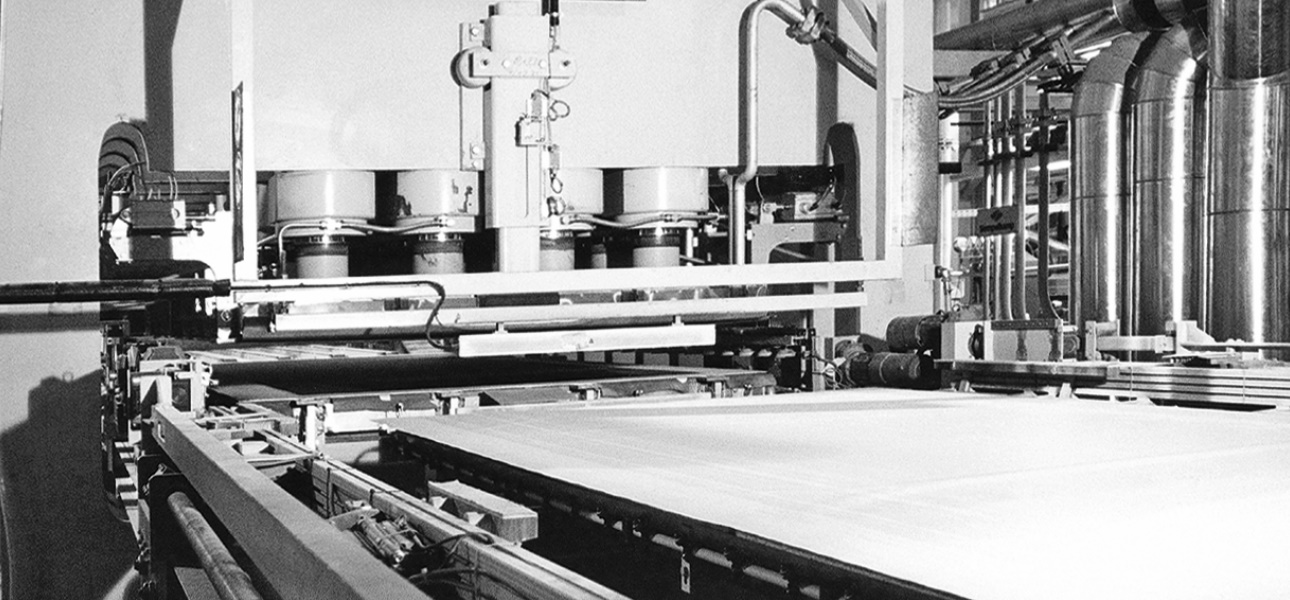

Applications in the area of wood-based materials processing are generally relatively simple 2D components made from standard materials. For some press insulators, a flexible compensation inlay to counteract inaccuracies in the mechanical structure is requested in addition to the insulation boards.