DOGLAS describes a range of thermosetting, glass-fibre-reinforced plastics (GFRPs) that combine various resin systems (e.g. polyester, epoxide and others) with different laying patterns (glass fabric, roving fabrics and mats) to effortlessly overcome the diverse challenges of today’s industrial companies.

DOGLAS material is used primarily in general mechanical engineering applications that call for high-specification components. Offering versatile use in temperature ranges up to 300°C, we will produce the right materials for you.

The individual components of DOGLAS materials are selected and combined to achieve the following properties:

- high mechanical strength

- very good dimensional stability

- temperature stability up to 300 °C

- low thermal conductivity

- good electrical insulating properties

- chemical resistance

- low water absorption

Doglas Materials

DOGLAS 200 LC is a composite material made from resin-bonded glass fibres with particularly low thermal conductivity. The application temperature is 200 °C and its thermal conductivity is 0.13 W/mK.

DOGLAS 220 M is a composite material made from resin-bonded glass fibres. The temperature resistance is 220 °C and the thermal conductivity is 0.22 W/mK.

DOGLAS 230 is a coating material made from resin-bonded glass fabric. The temperature resistance is 230 °C and the thermal conductivity is 0.23 W/mK.

DOGLAS 250 M is a composite material made from resin-bonded glass fibres. It is resistant up to a constant temperature of 250 °C and has thermal conductivity of 0.23 W/mK. In addition, it has very good electrical insulating properties. The creepage current resistance is CTI 600.

| Application temperature (°C) |

Compressive strength (N/mm2) |

Flexural strength (N/mm2) |

Thermal conductivity (W/mK) |

Linear thermal expansion coefficient (10-6 I/K) |

Electrical dielectric strength (KV/3mm) |

Creepage current resistance |

Combustibility UL94 |

||

| Permanent | Short term | at 23°C | at 23°C | ||||||

| DOTEX® 110 | 110 | 110 | 320 | 100 | 0.2 | 30 | 1.5 | CTI 100 | - |

| DOTEX® 120 | 120 | 120 | 300 | 135 | 0.2 | 30 | 10 | CTI 100 | - |

| DOGLAS® 155 | 155 | 210 | 250 | 130 | 0.3 | 22 | 36 | CTI 600 | V0 |

| DOGLAS® 180 E | 155 | 180 | 350 | 340 | 0.3 | 15 | 30 | CTI 180 | - |

| DOGLAS® 180 G | 180 | 210 | 600 | 450 | 0.3 | 15 | 30 | CTI 350 | - |

| DOGLAS® 180 H | 180 | 180 | 645 | 480 | 0.3 | 15 | 60 | CTI 225 | - |

| DOGLAS® 220 M | 220 | 230 | 500 | 350 | 0.22 | 10 | 39 | CTI 150 | - |

| DOGLAS® 230 R | 230 | 250 | 700 | 720 | 0.23 | 13 | 39 | CTI 500 | V0 |

| DOGLAS® 230 | 230 | 250 | 450 | 450 | 0.23 | 13 | 30 | CTI 200 | - |

| DOGLAS® 240 | 240 | 250 | 400 | 120 | 0.3 | 15 | 15 | CTI 450 | V0 |

| DOGLAS® 250 G | 250 | 260 | 570 | 400 | 0.23 | 20 | 30 | CTI 350 | - |

| DOGLAS® 250 M | 250 | 260 | 600 | 350 | 0.23 | 15 | 39 | CTI 600 | - |

| DOGLAS® 250 HQ | 250 | 260 | 660 | 780 | 0.23 | 12 | 39 | CTI 500 | - |

| DOGLAS® 280 | 300 | 320 | 500 | 250 | 0.3 | 10 | 20 | CTI 600 | V0 |

The values listed were determined on standard test specimens. The material properties may deviate from these values depending on the applications and component geometry. Please contact us for precise clarification of the material suitability. Other technical data on request. Subject to technical modifications and errors. 2014 edition.

Sample Solutions

EuroGrippers

The term “EuroGripper” refers, for example, to a mounting for welding tongs for spot welding, which is frequently used for car body construction. A comprehensive standard was developed for this type of machine.

Threaded bars made of GFRP material

Threaded bars made from glass-fibre reinforced plastics are suitable for a wide range of applications. The threaded bars are used to insulate threaded connections.

Gripper fingers

Gripper fingers have component-specific contours at their ends that enable them to pick up, grip, transport or guide components. They are used primarily in electronics manufacturing.

High-voltage insulation

What sets these types of insulators apart is the combination of different requirements that simultaneously apply to their implementation.

Complex 3D components for thermal insulation

The manner in which these insulation materials are implemented can be as varied as the requirements placed on them: from a simple intermediate layer all the way to complex 3D components with various material combinations that are produced on a 5-axis…

Nuts made of GFRP material

Our nuts made from glass-fibre-strengthened plastics are available as square or hexagonal nuts.

Blank holders

Blank holders serve to hold components securely in position in the application. They are typically held against a surface/contour.

Screw head insulation

During the process of pinning and screwing components, electrical insulation must frequently be guaranteed. Ceramic cylindrical pins ensure a positive connection while a steel screw provides for the positional connection - the interlocking connection…

Bobbin cores

Bobbin cores are usually round parts with a large groove into which a copper coil is wound. This coil induces a magnetic field in the centre of the coil.

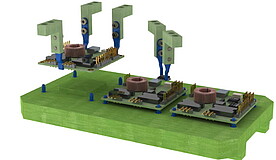

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Heat insulation board

DOTHERM and ISOCOS offer heat protection plates that are precisely adapted to the respective process requirements in terms of material, compression strength, temperature resistance and dimensional stability.

Non-material-specific insulation solutions

In many industrial applications, it makes sense to use multi-layered materials or material combinations.

Workpiece holder/carrier

The exact positioning of components is particularly important for series production. Here, multiple components are frequently welded, bonded, riveted, soldered, etc. at high cycle rates to form assemblies.

Show more Show less