The DOTHERM product range includes materials that have proven themselves first and foremost in high-temperature applications. DOTHERM materials are characterised by low thermal conductivity and outstanding electrical insulating properties.

The use of silicates and silicone resins as carrier systems makes it possible to work in temperature ranges up to 1,100 °C, to manage and protect processes in which other materials can no longer be used.

For area of IR plastic welding, we provide special solutions that are designed to meet the requirements of these types of plants.

| Application temperature (°C) |

Compressive strength (N/mm2) |

Flexural strength (N/mm2) |

Thermal conductivity (W/mK) |

Linear thermal expansion coefficient (10-6 1/K) |

Electrical dielectric strength (KV/3mm) |

Creepage current resistance |

Arc |

||

| Permanent | Short term | at 23°C | at 23°C | ||||||

| DOTHERM® 700 | 700 | 700 | 120 | 32 | 0.37 | 6 | 8.7 | - | > 370 |

| DOTHERM® 1000 | 1000 | 1000 | 35 | 18 | 0.50 | 6.4 | 14.1 | CTI 600 | > 420 |

| DOTHERM® 1100 | 1100 | 1100 | 16 | 7 | 0.1 | 7 | - | - | - |

| DOTHERM® 600 M | 600 | 600 | 410 | 150 | 0,26 | 10 | 75 | CTI 500 | > 420 |

| DOTHERM® 800 M | 800 | 800 | 400 | 150 | 0,26 | 10 | 75 | CTI 525 | > 420 |

| DOTEC® 200 | 200 | 220 | 330 | 100 | 0.3 | 13 | - | - | - |

| DOTEC® 280 | 280 | 300 | 150 | 30 | 0.28 | 20 | - | - | - |

| DOTEC® 350 | 350 | 400 | 38 | 20 | 0.12 | 40 | 20 | - | - |

| DOTEC® 500 M | 500 | 500 | 310 | 85 | 0.87 | 11 | 86.1 | CTI 600 | > 245 |

| DOTEC® 600 | 600 | 600 | 220 | 76 | 1.32 | 10 | 49.5 | CTI 600 | > 345 |

| DOTEC® 800 | 870 | 870 | 276 | 93 | 1.02 | 15 | 56.7 | CTI 600 | > 300 |

| DOTEC® 1000 S | 1000 | 1000 | 70 | 40 | 0.69 | 5.6 | 8.4 | - | > 600 |

| DOFLEX® MSP | 700 | 1000 | - | - | 0.2 | - | 60 | - | - |

| DOFLEX® CM 30 | 1000 | 1100 | - | - | 0.1 | - | 69 | - | - |

The values listed were determined on standard test specimens. The material properties may deviate from these values depending on the applications and component geometry. Please contact us for precise clarification of the material suitability. Other technical data on request. Subject to technical modifications and errors. 2014 edition.

Sample Solutions

Gripper fingers

Gripper fingers have component-specific contours at their ends that enable them to pick up, grip, transport or guide components. They are used primarily in electronics manufacturing.

High-voltage insulation

What sets these types of insulators apart is the combination of different requirements that simultaneously apply to their implementation.

Insulating components for plastic welding technology

A plastic welding process generates heat that must be insulated. The following applies: The shorter the cycle times, the greater the amount of energy that needs to be introduced into the joining zone.

Complex 3D components for thermal insulation

The manner in which these insulation materials are implemented can be as varied as the requirements placed on them: from a simple intermediate layer all the way to complex 3D components with various material combinations that are produced on a 5-axis…

Blank holders

Blank holders serve to hold components securely in position in the application. They are typically held against a surface/contour.

Screw head insulation

During the process of pinning and screwing components, electrical insulation must frequently be guaranteed. Ceramic cylindrical pins ensure a positive connection while a steel screw provides for the positional connection - the interlocking connection…

Heat insulation board

DOTHERM and ISOCOS offer heat protection plates that are precisely adapted to the respective process requirements in terms of material, compression strength, temperature resistance and dimensional stability.

Non-material-specific insulation solutions

In many industrial applications, it makes sense to use multi-layered materials or material combinations.

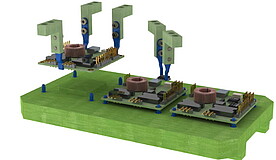

Goods carriers

Goods carriers are used to hold other products, such as circuit boards. In many cases, they must be electrically insulating, wear-resistant and designed to cope with thermal shock to enable smooth handling.

Show more Show less